Process Safety Management (PSM) is the identification, prevention, control, and mitigation of unintended release of hazardous materials or loss of primary containment that have the potential to become serious incidents (fires, explosions, mass injuries, fatality, etc.).

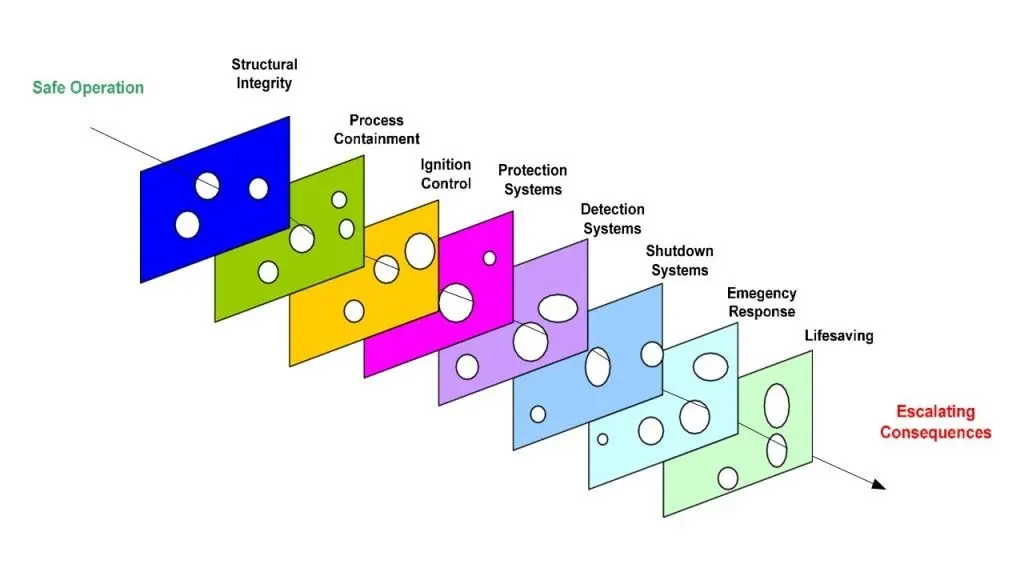

One of the key components to achieving a successful PSM is to create and maintain safeguards or barriers to prevent the release of hazardous materials and mitigate the effect/ consequence of those releases to personnel, asset, and the environment.

The safety-critical are those barriers or elements of an installation or plant that can be subjected to failure and substantially cause, contribute, prevent or help recover from a major accident hazard or event.

The Safety-Critical Element management involves the maintenance, inspection, and testing, and performance history to maintain SCE in suitable working conditions. Continual monitoring helps in the conformance and maintenance of SCEs in proper working conditions. Performance standards are those documents that lay the foundation for the expected performance from an SCE. A performance standard is typically defined as a set of requirements that constitute the basis for assurance tasks for safety-critical elements during design. Hence it is essential to develop and identify performance standards for the identified SCEs during the engineering or design stage.

SCEs and their Performance standards ensure that new installations or designs conform to good engineering practice and reliable engineering. For greenfield projects, it is extremely important that their design be robust and that they be able to perform their intended functions throughout their design life.

Also as the majority of oil and gas installations age, it is important to ensure that they remain capable of performing intended functions in the safest manner possible to avoid harm to personnel or to the environment. SCEs and their life-cycle-management processes help achieve these goals and reduce or prevent major accidents.

There are various methods to determine SCEs, based on the maturity of their process safety management systems, Hazard and effects management system(HEMS), and the type of risk assessments they have available

A broad guideline would be as below:

This is done using different hazard identification techniques, involving both qualitative and quantitative methods like:

This process allows the identification of all SCEs associated with the facility as well as detailing those systems deemed not safety critical with regard to causing or mitigating a MAE.

Note: There are several systems whose failed integrity could lead to serious harm/injury, e.g. pressurized release, exposure to chemicals, etc, but not necessarily a MAE. These systems are not identified as an SCE, as the consequence due to failure of their integrity is not severe enough to lead or contribute ‘substantially’ to a MAE. This determination has been made by reference to the results of the HAZID, and engineering judgement and experience.

The recommended model for developing Safety Critical Element Performance Standards is based on the Functionality, Availability, Reliability, Survivability and Interaction (FARSI) format where:

Interaction refers to the way that the Safety Critical Element in question is dependent upon other SCEs to operate or otherwise interacts with other SCEs

The results from this process are generally recorded in a Hazard Register or Risk Register or Hazard and Effects management register, which documents all the potential major accident event scenarios on an installation. Based on this register a comprehensive Major Accident Hazard (MAH) sheet is developed.

Identification of systems(equipment and instruments) that can prevent Major Accident Hazard(MAH)

From the review of the list/sheet of Major Accident Hazard developed from the above different HAZARD identification techniques identify the systems associated with each MAH.

SCE identification is usually carried out in the form of Bowtie Workshop (usually utilized by using Bowtie Software), which comprises a multidiscipline team consisting of engineering, operations, maintenance, etc. This will ensure there would be enough technical know-how of the major accident pertaining to the installation. Starting from the complete list of equipment(PFD, block diagram, etc) the team should assess each item to ascertain as to whether it could prevent or help recover from a major accident.

Based on the outcome of this workshop, a list of Safety and Environmentally critical element list and Safety and Environmentally critical tasks are derived. for the MAH for which SCE has not been assigned, proper reasoning should be assigned as to why an item has not been identified as safety-critical and with reference to the relevant major accident hazard.

Once the SCE has been identified it is paramount to define its function in terms of a Performance Standard. These are like criteria that one needs to define, based on which we can measure the performance of SCE. The performance standards are defined based on:

SCE and performance standards are input to the Safety register or operation safety case. Based on the Performance Standard, assurance tasks can be defined in the maintenance system to ensure that the required performance is met during operation analyzing the data in the maintenance, the system guarantees that all the SCEs required to manage Major Accidents are functioning correctly. If there are deviations to the agreed performance standards corrective actions can be taken to restore the integrity of the systems.

In summary proper identification of Safety-critical elements and defining their performance criteria during the Engineering phase is absolutely critical to prevent and Mitigate Major Accident Hazards during the operational phase of installation.

The safety critical elements are those parts of an installation or plants that can be subjected to failure and substantially cause, contribute, prevent or help recover from a major accident hazard or event. It is essential to develop performance standards for the identified SCEs. The SCE life cycle management involves alignment of maintenance, inspection and testing and performance history to maintain SCE in suitable working conditions. Continual monitoring helps in conformance of SCEs by Performance Standards.